Surface-tolerant epoxy mastic coatings have been a versatile, forgiving corrosion protection solution in certain applications for decades.

Why? What makes them so good?

It has to do with their chemistry: The pasty, sticky consistency and relatively impermeable character of mastic resins makes them great in any application where moisture resistance is important. That viscous stickiness also imparts good flexibility and a low-stress cure, making these coatings suitable for corrosion protection over surfaces that have not been—and sometimes cannot be—prepared via abrasive blasting.

The following sections expand on the common scenarios in which this versatile product type is specified:

- • As a normal component of corrosion protection in select markets such as marine

- • When traditional surface preparation via abrasive blasting would compromise an asset, threaten the environment, or is infeasible due to space constraints

- • When abrasive blasting to achieve certain surface profiles is not necessary and can be avoided to save time and money

- • On fast-track or emergency maintenance coating projects

A staple for asset protection

Surface-tolerant epoxy mastics are widely used for corrosion protection of marine vessels and infrastructure, in both new-build and maintenance scenarios.

The onerous and time-consuming process of dry-docking a vessel helps explain why these products are so popular for maintaining hulls. Any vessel up on blocks is one not underway and earning revenue, so owners are always eager to return it to service quickly.

Often, only spot blasting and touch-up coating are needed to fully protect a ship’s hull until its next mandatory dry-docking. Products like Carbomastic 15 are popular as maintenance primers because they perform well over existing coatings in good condition, minimizing vessels’ days out of water.

One reason they are able to accomplish this is due to their low-stress cure characteristics. Typical epoxies exert stresses ranging from 700 to 1,500 psi (4,826 to 10,342 kPa) on underlying films, and elevated stresses within that range are sufficient to pull an existing coating off the substrate. Conversely, product testing data show that Carbomastic 15 exerts no more than 500 psi (3,447 kPa), and as little as 59 psi (407 kPa), of pressure on an underlying film. The risk of disbondment at those levels is significantly reduced.

How long a coating lasts depends on its chemistry, whether it was properly applied, and how abusive its service has been. But this case study shows at least 12 years of service for Carbomastic 15 applied to an ocean supply vessel.

For new-built assets, the Carbomastic 615 variant is commonly specified. This inert-flake reinforced epoxy mastic boasts excellent resistance to fresh- and saltwater exposure, as well as exceptional moisture tolerance during application.

When external limitations forbid “ideal” surface prep

Another common use case for mastics is when conventional abrasive blast surface preparation would threaten the integrity of an asset or be ecologically detrimental.

In the former case, certain assets cannot be abrasive blasted prior to coating because of how they’re made. A real-world project best illustrates the scenario.

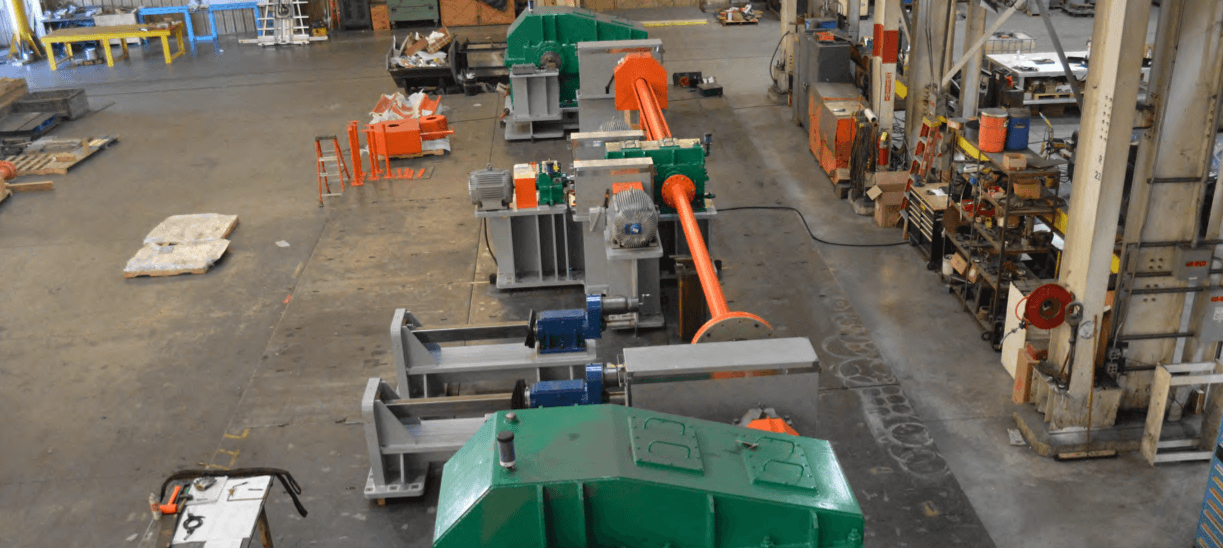

As of this writing in mid-2024, the Massachusetts Department of Transportation (MassDOT) is replacing the bridge carrying Western Avenue over the Saugus River in metropolitan Boston. A powerful motor will lift a 500,000-pound (226,800-kilogram) section of the bridge so boats can pass underneath.

The way that motor was built influenced corrosion protection specification. The motor consists of sensitive couplings, floating shafts, gears, and reducers which were designed for assembly in a process involving high heat. Any coating applied prior to assembly would have been damaged at high temperatures, so instead, the coatings would be applied afterward. But the motor’s interior components are so sensitive and costly to replace that abrasive blasting prior to coating application was ruled out over the risk that errant blast media would find its way into the machinery.

With these limitations in mind, the Alabama fabrication shop where the work occurred elected to use Carbomastic 15 instead of a more conventional primer due to its adhesion characteristics over a surface that could not be blasted.

In the case of environmental restrictions, consider another real-world scenario: The St. Regis Kanai beach resort in Mexico is located within a mangrove forest. Mangrove forests perform vital ecological functions and are tightly protected in some jurisdictions. In this case, the location of some of the structural steel comprising the resort’s construction was within a boundary where abrasive blasting is forbidden.

As with the bridge in Massachusetts, when external circumstances change, the corrosion protection calculation changes, too. Carbomastic 615 was specified in those more sensitive areas, first because it would adhere well to a steel surface that could not be abrasive blasted, but also because it would apply well and cure adequately in an area where moisture was harder to control.

This case study describes the project.

A compelling cost- and time-saver

The case of a barge in Louisiana demonstrates how the upside of a low-stress curing product over an existing coating does not come accompanied by a downside in poor adhesion in its own right.

When a paperwork mix-up omitted surface preparation instructions from the coating specification, the barge owner wondered whether they could proceed with coating anyway rather than restarting the project entirely and delaying the barge’s return to revenue service.

This case study reports on positive adhesion test results following the application of Carbomastic 15 to marginally prepared interior voids of the barge instead of a conventional primer that would have required additional blasting.

Another compelling case is that of a refinery in the Gulf region of the U.S. owned by a global chemical company. A survey of some of the site’s storage tanks revealed that a small handful of them were in dire need of service. Each of those tanks’ cone-type roofs had never been coated; they’d sat unprotected and weathering for 20 years. And some of the tanks had been repaired with patches welded to their shells, some of which had not been completely protected.

When an incumbent coating provider insisted on a full blast of the tanks, the owner began investigating alternatives on the hunch that a simpler, faster, and less costly solution would be sufficient.

A Carboline technical representative observed that the conditions of the tanks supported the recommendation of a coating system anchored by Carbomastic 15 instead of a more conventional primer. This more efficient maintenance program was agreed.

Of course, each facility’s circumstances differ. Subbing out a traditional system for an alternative might not be the right move. If it isn’t, we will say so.

Offering flexibility and freedom

Owners across markets and applications encounter a wide range of corrosion prevention and asset protection challenges.

Sometimes, surface-tolerant epoxy mastics are the textbook solution. Other times, they come out of left field but nonetheless work phenomenally.

It’s important to stress that these products—whether ours or someone else’s—are no silver bullet. They’re instruments of flexibility, not corner-cutting, and responsible technical experts know the difference.

But we hope this survey of strong performance in a variety of circumstances offers a wider view of possible solutions to familiar problems. You might have more options than you think.