Rail tank cars are essential to global distribution networks.

They’re a safe, reliable, and comparatively cheap way to move a huge volume of commodities where they are needed.

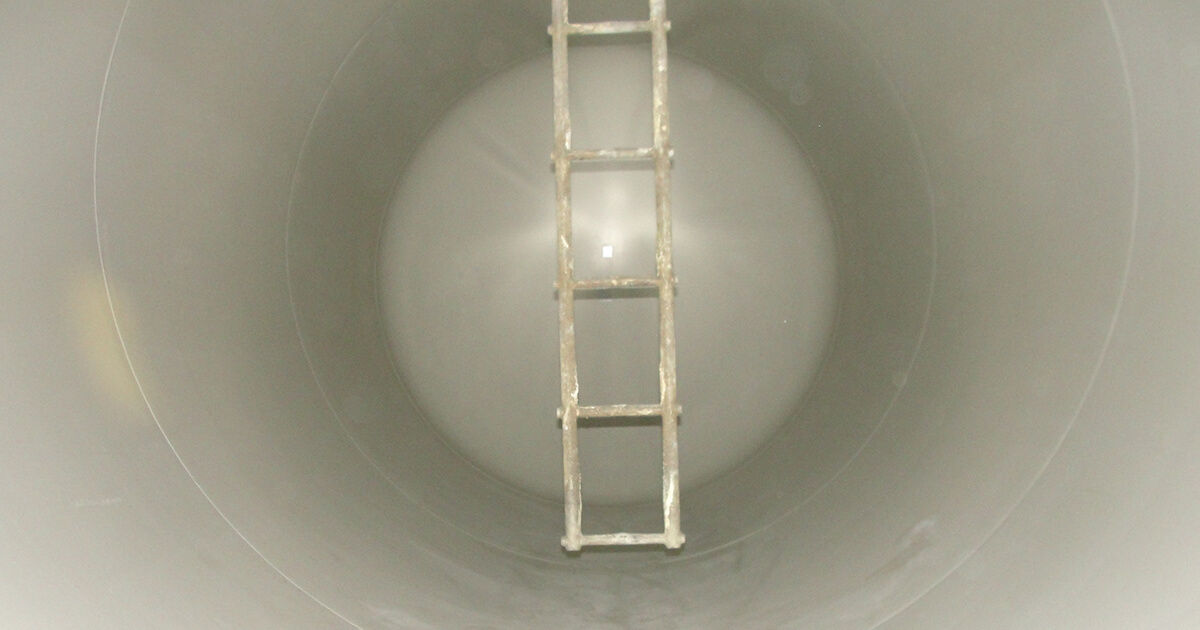

One contributing factor to their safety is the protective linings applied inside rail tank car shells. Proper selection of interior linings ensures years (and sometimes decades) of protection against corrosion of the tank car substrate and purity of lading in transit.

This is Part 1 of a three-part series. Additional articles in this series will cover tank car lining inspections and lining repairs.

How Cargo Shapes Rail Tank Car Lining Selection

Industrial processes rely on pure, uncorrupted commodities to assure final product quality. That purity is doubly important when the products are meant for human consumption and are therefore heavily regulated by health and safety authorities.

Rail tank car linings are effective in maintaining this purity provided they are selected to match the chemical characteristics of the commodity they’re meant to protect. (We confine this discussion to liquid-applied products. Solid linings—rubber being the prime example—are not considered here.)

Epoxy linings (including amine, polyamide, cycloaliphatic, novolac, or phenolic epoxies) in general perform well against a wide range of exposures and so are the most commonly specified lining systems.

Baked phenolics offer excellent resistance to acids and solvents and are commonly specified for tank cars hauling non-corrosive material. These are uniquely well-suited for hauling phenols, which are important ingredients in medicines, plastics, and explosives. As the name implies, these thermoset linings require an elevated temperature for full crosslinking. That process takes several hours at a minimum, and up to several days depending on what product is specified and how many coats are applied. Read more about baked phenolic railcar linings here.

Vinyl esters are specified when cargo is more corrosive than epoxies can withstand, but not so corrosive that a rubber lining is needed. Sodium bisulfate and sodium chlorate are common ladings for rail tank cars lined with vinyl esters. Thick-film vinyl esters are often specified as maintenance linings.

Thermal requirements impact lining selection, too. Very hot or very cold conditions will influence lining performance.

Treat the generic information above as a conversation starter with a coating manufacturer or applicator. These experts will consult product testing information and field performance history to direct you to the lining product that’s best for a tank car’s intended service.

Do Substrate Condition and Remediation Influence Rail Tank Car Lining Selection?

Federal regulations mandate tank car lining inspection cycles that are intended to catch and address lining failures or corrosion when the corrosion rate of a commodity is equal to or greater than 2.5 mils per year.

Typical rail tank car lining products are formulated to last longer than the maximum eight-year mandatory inspection interval for cars carrying corrosive commodities in the U.S., but design life and service life don’t always match. Any combination of the following can result in lining failure:

- • Errors not detected or addressed during manufacture or application of the lining

- • A car entered multiple service by mistake and hauled cargo incompatible with its lining

- • Improper cleaning of the tank car between services

- • Mechanical or thermal damage during service compromised the lining

What’s more, lots can happen in the interval between inspections and requalification. Linings often hold up just fine after their first inspection, or two, or even three. But you can see the potential problem: The more inspections a lining passes, the more likely a problem will occur prior to the next one.

And whatever the reason why, these linings fail. When that happens, the steel beneath them is likely to degrade.

In the U.S., federal law regulates how much material loss a rail tank car can sustain and still qualify for service. Maintenance lining systems are available for application over pitted or otherwise corroded steel that fill in voids and prevent additional damage from occurring. Then, a traditional lining is applied.

Selecting the ideal system is more complicated in this case. In addition to understanding a lining’s compatibility with cargo, coating manufacturers or applicators must also contend with its relationship to the product applied to the substrate.

The difficulty can be avoided with a thorough review of tank car decontamination processes, lining application methods and product selection. The best maintenance is prevention, especially regarding the most intensely corrosive commodities.

Proper Lining Selection Only Goes So Far

Selecting the right rail tank car lining is not always easy. You’ll get better mileage in partnership with knowledgeable coating manufacturers and qualified applicators.

So, you’re one-third of the way there.

Inspecting the lining is the next leg of the journey. That’s in Part 2 of this series, which we'll publish soon.